Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

|

|

Christian Feldmann | Louis Stephan | Arnaud Berchouchi |

ConsultantAICVF MemberREHVA Fellowch.feld@yahoo.com | Head of R & D DeptVMI-VENTILAIRSEClouis.stephan@vmi-technologies.com | Ventilation Systems EngineerVMI-VENTILAIRSECarnaud.berchouchi@vmi-technologies.com |

In France, since the 1980's, Supply ventilation systems were first used in the renovation of existing dwellings, then in new buildings. New fields of use, in particular in small tertiary buildings, are now opening up to this technology. The application to a nursery is analysed in this article.

This process has been implemented in a collective day care centre (nursery) located in the southern Parisian suburbs and has been the subject of an instrumented follow-up of several months.

Two “activity rooms” for older children were equipped with this ventilation process.

One of these two rooms was instrumented to measure the concentration of CO₂, TVOC and solid particles PM2.5.

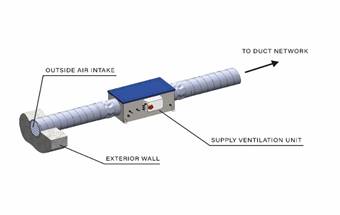

The air supply to the rooms is ensured by air vents connected with an supply ventilation unit which takes the fresh air from outside. The supply ventilation unit consists of a fan, filter and preheater. (Figure 1)

Figure 1. Supply ventilation unit and connections to outside air intake and air distribution network.

The airflow in the rooms served is controlled by an algorithm that adapts the fan speed to the set values of the CO₂ concentration.

The supply ventilation unit is installed in an adjacent room. A network of ducts ensures the routing of air between the ventilation unit and the air vents located in the rooms.

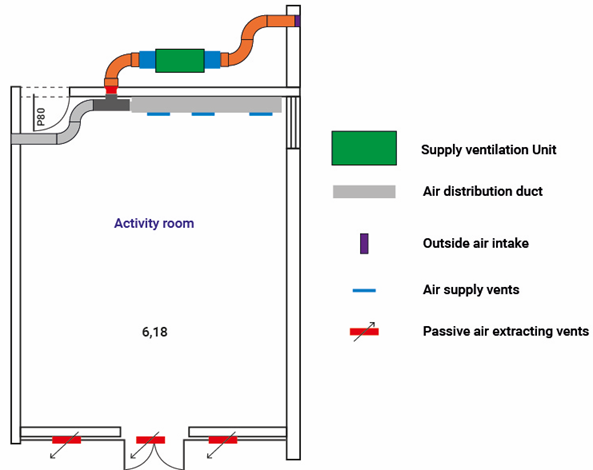

An example of the installation of a supply ventilation system in a nursery is illustrated in Figure 2.

Figure 2. The fresh air taken from outside the building and after passing through the ventilation supply unit is routed through the distribution network to the various premises of the nursery. Air is evacuated outside by passive exhaust vents mounted on the windows frame.

The studied room, one of the activity rooms of the nursery, of a surface of 48 m², has a completely glazed frontage. It communicates directly with the outside by a double door. The glazed facade has in the upper part two small windows of a surface of 0,30 m² each.

Two passive air extracting vents are located in the frame of each of the windows.

The mechanical airflow to the rooms is controlled by an algorithm that adapts the rotation speed of the fan according to the setpoint values defined for the CO₂concentration.

The supply ventilation unit is installed in an adjoining room. A network of ducts ensures the routing of the air between the unit and the supply vents arranged in the rooms. Passive air extracting vents ensure the evacuation of air.

Figure 3. Ventilation system diagram.

The indoor air quality is evaluated by measuring the following characteristic quantities:

· Temperature (°C) by: E4000NG Nanosense sensor (accuracy ± 0.3°C)

· Relative humidity (%) by: E4000NG Nanosense (accuracy ± 2%).

· CO₂ concentration by: E4000NG Nanosense sensor - NDIR technology (accuracy ± 50ppm).

· Concentration of total VOC by:E4000NG sensor (SnO2 (tin dioxide) semiconductor metal oxide sorption technology, accuracy ± 15%).

· Concentration of fine particles (PM10, PM2.5, PM1) by: P4000NG sensor (Laser diffraction process), accuracy ± 15%.

The concentration of CO₂, Total VOC and PM is measured and recorded by the sensors. On each sensor an interface allows the recovery of recorded data.

It was not possible, at the risk of being opposed by the management of the establishment or the lack of cooperation of the staff, to impose methodological constraints that were too strong for this measurement campaign.

The approach finally retained allowing a realistic evaluation of the performances of the system, taking in account the required limited disturbing the current practices of the use of the room is as follows:

· The period of measurements includes two weeks of operation with the supply ventilation system followed by two weeks of operation of air renewal by simple opening of the doors and windows.

· The manoeuvres of opening and closing of the external door, which correspond, partly, to the entries and exits of the children, and of the windows are left with the free choice of the nursery staff. The latter are kept informed of the operating status of the ventilation (days "with" and days "without" operation of the supply ventilation system) but without any particular instruction concerning the opening of the windows being imposed on them.

The data analysed correspond to the periods of occupation of this room during two consecutive calendar weeks, excluding weekends (the nursery being closed), from Monday to Friday and from 8 am to 7 pm.

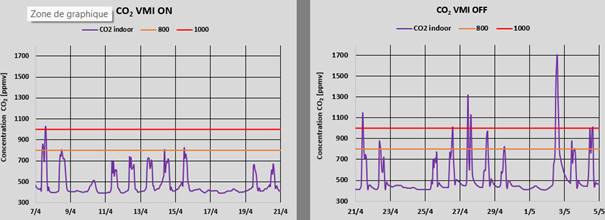

The following compares the concentrations of pollutants measured in the room during the periods,

· of operation of the supply ventilation system

· of air renewal by simple opening of the doors and windows

It is noted that, during operation of supply ventilation system, CO₂ concentration does not exceed 1 100 ppm. This reaches 1 700 ppm during the operating phase by simply opening the doors and windows.

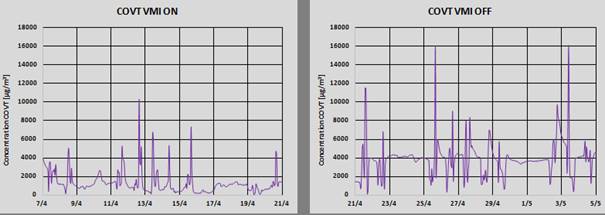

Figure 5. Evolution of the TVOC concentration - The curve on the left corresponds to the case where the Supply Ventilation System is in operation, the one on the right to that where the renewal of air is ensured by the opening of the doors and windows.

We note strong amplitudes of the TVOC concentration for the two operating modes.

The average TVOC concentration calculated for the two operating modes is:

· during operation of Supply Ventilation System: 1845.29 µg/m³ ± 291

· during air change by simple opening doors and windows: 3638 µg/m³ ± 503

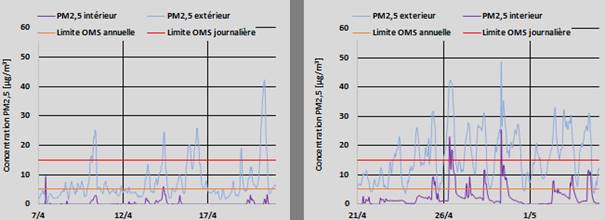

Figure 6. Comparative changes in the concentration of Particles Matter (PM2.5) between outdoor and indoor air, with Supply Ventilation System in operation (left) and by simply opening doors and window (right).

It should be noted that, during the supply ventilation operating sequence, the PM2.5 concentration in the indoor air of the room does not exceed 2 µg/m³ while the air renewal is higher. We note the very clear damping effect of the indoor concentration in response to the outdoor concentration peak, linked to the presence of a filter in the supply unit.

The dynamics observed when air renewal is ensured only by the simple opening of doors and windows is very different, in the latter case the internal concentration frequently exceeds the thresholds defined by the World Health Organization.

The controlled introduction by mechanical supply of fresh air directly into the premises makes it possible to maintain the concentrations of three characteristic pollutants at levels well below the threshold values prescribed by the WHO.

Such a device allows, in addition to the adaptation of the flow, an effective filtration of the outside air introduced into the premises. It also authorizes, when the configuration of the premises lends itself to it, to install the air intake in the zone where the outside air is the least locally polluted (in a courtyard or an interior garden for example, rather than on the facade facing the street).

Follow us on social media accounts to stay up to date with REHVA actualities

0