Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

Ralf Kästle |

Head of Divison PM Air+ |

In commercial buildings with mechanical ventilation, it has been common practice for many years to allocate ventilation costs to the various building occupants according to a pre-defined allocation key. Currently, this key is primarily based on the floor area utilized by each tenant/occupant in relation to the total ventilated area of the building. Other influencing factors, such as different operating times and room utilization, are estimated and, if considered at all, incorporated through weighting factors. The reason for employing this cost allocation method lies in its ease of implementation and the absence of alternative options. A notable drawback of this approach is that it does not motivate for individual energy savings.

However, with energy prices on the rise and the imperative to reduce energy consumption in buildings in coming years, there is a growing need for methods to support individual energy savings. Consequently, in Germany for instance, the Buildings Energy Act (GEG) §6 "on the distribution of operating costs and on billing and consumption information" [1] requires that the operating costs of ventilation and air-conditioning systems should be allocated to occupants in a manner that takes their energy consumption into account. Additionally in Germany, the guideline VDI 2077 Sheet 4 provides specifications on how to record and bill costs for mechanical ventilation based on actual consumption.

In the latter guideline, essential components for accurate cost accounting are air-energy meters. They measure the volumetric flow of air and calculate the energy supplied from the enthalpy difference before and after the air conditioning. Consequently, a product standard has been developed in Germany to outline the requirements that calibrated air and air-energy meters must adhere to [3].

However, if air-energy meters are to be used for recording energy costs in accordance with this standard, several additional devices will need to be installed. Due to the additional costs, it may well be that these devices will not be implemented thereby perpetuating the standard practice of charging per utilized area.

Below we present an option, i.e. a system design for recording energy costs on the ventilation side without requiring the installation of any additional devices. It bears many similarities to the proposal in [3] for "dynamic consumption cost allocation with variable airflows using air meters". However, a crucial difference lies in the fact that the air volumes are measured by the usually already installed volumetric flow controllers, rather than by separate air meters.

When it comes to consumption-based billing of ventilation costs with volumetric flow controllers, the following two, albeit conflicting requirements are important and must be considered. Firstly, it should be possible to record the individual air volumes obtained with their respective costs. This transparency aims to increase tenants/occupants awareness of their individual energy consumption. However, this alone is insufficient, as the achieved air volumes also have a direct impact on the air quality within each room in the building.

Under-supplying rooms with air motivated by costs savings ought to be avoided because it will have an impact on the well-being and health of the room occupants. Consequently, it becomes evident that the supplied air volume must be controlled according to the number of people within each room of the building.

Nowadays, this is commonly achieved by using CO₂ sensors to measure air quality either in the rooms or within the extract air. The air volume flow in the room will then be modulated between a minimum and a maximum in respect to the present CO₂ levels. This procedure is commonly referred to as "demand-controlled ventilation" (DCV) [4]. The subsequent chapter describes the system design that is suitable for both consumption-based billing of ventilation costs and DCV. Furthermore, it addresses various aspects that need to be considered during the planning phase. Finally, we discuss the advantages of this method and point out its limitations in application.

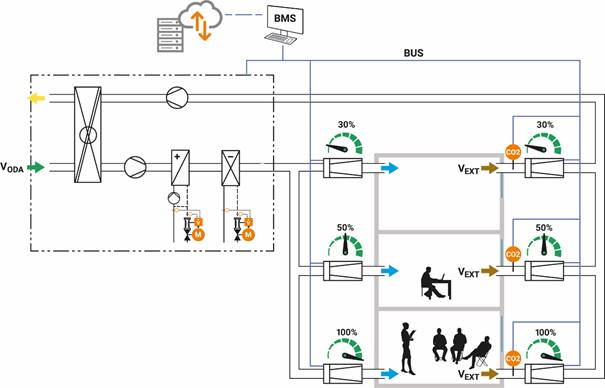

The mechanical ventilation of a building usually involves 2 stages: air conditioning and air distribution. In the air conditioning stage, fresh outdoor air is conditioned using an air handling unit and then supplied to the rooms through a duct system. Volumetric flow controllers are used to modulate the air flow. Figure 1 schematically illustrates an example of such a system, comprising an air handling unit and various rooms or zones.

To measure the CO₂ concentrations, sensors are installed in the extract air ducts. Alternatively, the CO₂ levels can also be measured using room sensors. As mentioned earlier, the air volumes supplied are controlled according to the DCV procedure.

Figure 1. A building with an air handling unit (dashed outline) for air conditioning. The supply air to the 3 rooms with different occupancy is adjusted by means of volumetric flow controllers. The data from the air handling unit, the volumetric flow controllers and the CO₂ sensors in the extract air are transmitted to the building management system via bus connection.

For the correct calculation of ventilation costs in a building it is imperative that the air conditioning unit and the components for air supply and control in the rooms are interconnected. This connectivity shall carefully be considered during planning phase. The following key points should be noted:

· Record, evaluate, and store the partial volumetric flows of all outlets downstream of the air handling unit, uniquely assigning these flows to the different occupants.

· Ensure digital connectivity between the air handling unit, the volumetric flow controllers and CO₂ sensors in the various zones and the building management system.

· Transfer large data volumes via a bus to the cloud storage within the building automation and control system (BACS).

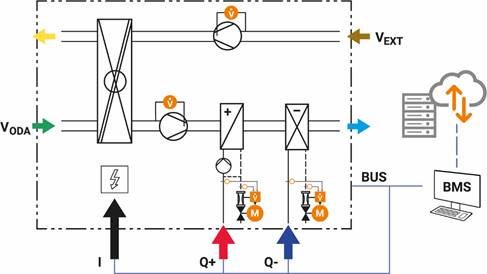

The air handling unit used to record ventilation costs is shown in more detail in Figure 2. The following aspects are crucial during the design and planning of the air handling unit:

- The total volumetric flows of the AHU can be determined by measuring the differential pressures across the supply and extract fans along with the specific conversions for the fans (k-factors).

Figure 2. Schematic diagram of the air handling unit. VODA and VEXT are the volumetric flows of supply and extract air of the air handling unit. I: Total electrical consumption of the air handling unit measured with an electricity meter. Q+/Q-: Quantities of heating and cooling supplied to the coils.

· The output power of the heating and cooling exchangers are each controlled, with a valve on the water side, flow sensor and two temperature sensors in water supply`s flow and return. This information enables the user to calculate the power output of the exchangers for heating and cooling.

· The overall electric consumption, encompassing all components of the air handling unit, is recorded via a central electricity meter.

Once the requirements for the air handling unit are met as listed above, the total energy required for air conditioning per unit of time is known. Together with the supply and extract air volumetric flows, this information serves as basis for calculating the ventilation costs.

Energy valves are now commercially available to control and measure the energy output of the heat exchangers, respectively. In addition, they ensure water flow control that remains unaffected by water pressure fluctuations occurring within the building`s heating and cooling networks. Furthermore, these valves provide transparency in terms of flow, temperature, and heat transfer at the heat exchangers. This transparency will be the basis for further optimization, ensuring optimal operation [5,6].

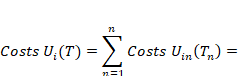

The allocation of energy costs to the

consumer Ui within a given period ![]() with time

intervals Tn now proceeds as follows:

with time

intervals Tn now proceeds as follows:

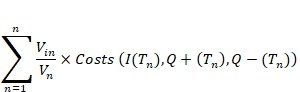

The total energy costs for consumer i are calculated by summing up the costs determined for that consumer in all measured time intervals Tn. The costs in the time interval Tn are calculated from the total costs for the respective interval in proportion to the air volume Vin obtained by each occupant relative to the overall Volume Vn in the respective time interval.

To simplify the implementation, "virtual" electricity, heat, and cooling meters can be created in the building management system software for each occupant. These virtual meters can accurately track the energy consumption of each occupant. In practice, the amount of energy consumed every 15 minutes can be entered into these meters. To improve measuring accuracy, multiple readings can be taken within the 15-minute period, with only the average value being reported. Finally, the costs for each consumer/occupant can be calculated using the prices for each type of energy.

The proposed method of calculating ventilation costs is based on recording the energy supplied by means of meters for electrical current, heating, and cooling at the air handling unit. The allocation of the energy consumed, and the costs incurred is done according to the volume of air received by each occupant. While this procedure is a simplification and does not consider all energy-related influences, it can be used under the following assumptions. Firstly, it assumes that the airflows delivered to the occupants are all at the same temperature and air humidity. Second, the influences of long ventilation ducts or local reheating are not considered here. In addition, it assumes that the various occupants will also contribute to the heat recovery in proportion to their share of the air volumes obtained.

In good practice, when designing a ventilation system with the goal of achieving good indoor air quality, consulting engineers often design a system that is close to the proposal here. This means that only minor adaptions are necessary to enable the billing of mechanical ventilation costs when planning a ventilation system for DCV.

Controlling the air supply based on the CO₂ content in the rooms ensures that fresh air is only supplied where it is needed most. By additionally implementing a "fan optimizer control algorithm" [4] in the supply air and extract air of the air handling unit, the energy consumption of the ventilation system is minimized, as the resistances of the VAV dampers in the ventilation ducts are at their minimum.

Another benefit of this method is the double measurement of the air volumetric flow directly at the fan on the generator side and with the volumetric flow controllers at the other ends of the air ducts. Comparing the measured values allows easy assessment of the tightness of the air ducts.

Currently, electrical current, heat and cooling meters are available in the market as components that are certified by calibration authorities for billing purposes. However, VAV controllers including boxes manufactured by various vendors may not meet today's requirements for an "air meter". Nevertheless, with proper handling and calibration, they provide high measuring accuracy, sufficient for cost allocation.

Since the procedure presented is not fully certified, its implementation needs a contractual agreement between the building operator and the occupants. In contrast to the billing per occupant area, the method outlined allows the operator to allocate the costs of air generation to the occupants based on their actual consumptions. This approach is fair as it takes into consideration the behavior of each individual occupant.

[1] Bundesministerium für Justiz, Gesetz zur Einsparung von Energie und zur Nutzung erneuerbarer Energien zur Wärme- und Kälteerzeugung in Gebäuden* (Gebäudeenergiegesetz - GEG [Buildings Energy Act]), § 6

[2] Verein Deutscher Ingenieure, 2019. Verbrauchskostenerfassung für die technische Gebäudeausrüstung [Energy consumption accounting for the building services], VDI2077 Sheet 4, VDI Guidelines

[3] DIN 94701, 2021. Lufttechnische Systeme – Luftzähler und Luftenergiezähler – Anforderungen [Ventilation systems – Air meters and air energy meters – Requirements]

[4] Litiu, Andrei, 2017. Introduction to Building Automation Controls and Technical Building Management, REHVA Guidebook No. 22, Chapter 5.4 Ventilation written by M. Keel

[5] Marc Thuillard, Forest Reider, Gregor P. Henze, 2014. Energy Efficiency Strategies for Hydronic Systems through Intelligent Actuators, Ashrae Winter Conference

[6] Gregor P. Henze, Walter Henry, Marc Thuillard, 2013. Optimierung von Kaltwassersystemen auf dem Campus mit intelligenten Regelventilen: Eine Feldstudie. [Optimisation of Campus Chilled Water Systems with Intelligent Control Valves: A Field Study.] www.belimo.com

Note: AI tools were used to create certain parts of this article.

Follow us on social media accounts to stay up to date with REHVA actualities

0