Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

|

|

Johannes Simola | Risto Kosonen | Simo Kilpeläinen |

M.Sc, Energy Efficiency ExpertLassila & Tikanojajohannes.simola@lassila-tikanoja.fi | Full-ProfessorAalto University | D.Sc., laboratory managerAalto University |

To reach the emission targets, the primary energy consumption of the buildings has to be reduced and efforts must be made to use decarbonized heat production methods. Using waste heat and using renewable energy sources (RES) with heat pumps (HPs) are very effective ways to reduce heating power demand and energy consumption. With the help of hybrid heating systems, which combine different heat generation methods, it is possible to achieve low carbon dioxide (CO₂) emissions. However, to reach the full potential of these systems, the operation should be always guaranteed.

Hybrid heating systems are becoming more technical, and they can utilize several heat sources. The commissioning process and monitoring of system operation become very important issues in guaranteeing the cost saving targeted.

In this study, the commission process of eight real estates was analyzed. The handover of those buildings happened 1-4 years ago. All the case buildings were located in Southern Finland and equipped with modern automation systems.

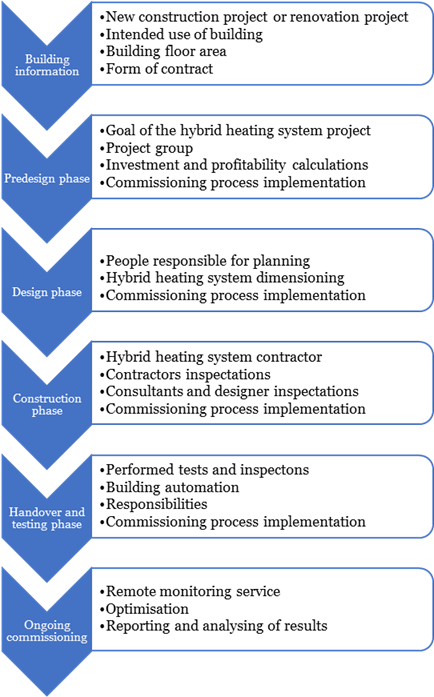

Hybrid heating system implementation, operation, and the commissioning process were analyzed in the case buildings. Design documents related to the hybrid heating system project were also obtained from some of the case buildings. With the help of an initially created checklist focusing on different phases of the construction process, the key personnel were interviewed (Figure 1). Thus, an insight into the implementation and commissioning process of the hybrid heating system, from project predesign to system operation and follow was obtained. Interviewed stakeholders included HVAC designers, consultants, supervisors, equipment suppliers, customer representatives, and contractors.

Figure 1. Basic information collected of the case buildings.

The eight case buildings that were the subject of the research and interviews varied in gross floor area between 9 000 m² and 100 000 m², so large properties were chosen as the case buildings for the study. The types of properties included residential buildings, office buildings, schools, shopping centers, and multi-purpose buildings.

In Table 1, a description of the case buildings is presented. In the table, the type of building, the building size, and the type of hybrid heating system are shown.

Table 1. Description of case buildings.

Case building No. | Building type | Building size | Hybrid heating system model |

1 | New residential building with grocery store and few business spaces | 9 000 m² | GSHP with grocery store waste heat and wastewater heat recovery. Free cooling with wells. DH as top up heating and DC as top up cooling. |

2 | New School building | 9 000 m² | GSHP with DH. Free cooling with wells. |

3 | New School building | 10 000 m² | GSHP with DH. Free cooling with wells. |

4 | Renovated Apartment building area | 29 000 m² | GSHP with DH. Free cooling with wells. |

5 | Shopping centre | 100 000 m² | HP with grocery store waste heat recovery, exhaust air heat recovery, cooling network waste heat recovery. DH as top up heating. |

6 | Renovated commercial building | 12 500 m² | AWHP with booster HP. DH as top up heating. |

7 | New apartment building with offices and market | 14 000 m² | HP with DC return connection. DH as top up heating and DC as top up cooling. Area heating and cooling network. |

8 | Combination of office/education buildings properties | 33 000 m² | AWHP low temperature area heating and cooling network. DH as top up heating and DC as top up cooling. |

The commissioning process is not understood in Finland as it is described in the ASHRAE and REHVA guidelines [1,2,5]. In Finland, it is understood purely cover the testing and handover phases. The reason for this is related to the instructions in the Finnish RT HVAC commissioning guidelines, where the commissioning process is started during the construction phase [3-4].

When the commissioning process is not started earlier than the construction phase, it cannot address the errors and problems that appear in the project predesign and detailed design phases. In all the case buildings investigated in this study, the RT instructions on the HVAC commissioning process were at least partially followed in the operational verification. The RT instructions guideline on commissioning are quite comprehensive and considers also heating and cooling systems [3-4]. However, it was possible to notice from the case buildings that they had not been implemented as comprehensively as stated in the Finnish RT instructions [3-4]. Some of the process steps were clearly omitted in the case buildings.

The title of commissioning provider is quite often confused with HVAC supervisor. In the case buildings, it was noticed that the qualification of HVAC supervisors is not necessarily sufficient to supervise the implementation of complex hybrid heating systems.

Regarding the case buildings’ hybrid heating systems, the commissioning process was performed in different ways. There did not seem to be a clear uniform commissioning method between the case buildings. The methodology of the implemented commissioning process is very much dependent on the persons involved in the hybrid heating system project. Some of the case buildings, where a hybrid heating system project group was implemented already in the project predesign phase, worked exemplary. When the overall responsibilities of the involved persons had been defined, the commissioning process had been carried out with higher quality.

In three case buildings analyzed, the implementation of the hybrid heating system was subcontracted in the building construction project, and the commissioning process was mainly the responsibility of the general HVAC supervisor, who was also the supervisor of another HVAC system. In one case building where hybrid heating system implementation was carried out by the HVAC supervisor, many problems were found in the operational tests. Problems generally led to repairs during the warranty period. Deficient commissioning processes were carried out in three case buildings. The professional skills of the people involved in the hybrid heating system commissioning process can be considered to have a direct connection to the commissioning implementation and hybrid heating system operation.

In three case buildings hybrid heating systems worked very well. In all the other five case buildings, problems were found that affected the operation of the system. The most common problems were related to heat collection, automation, or installation errors. The hybrid heating system of all case buildings included at least two or more heat sources. Free cooling either from the geothermal well field or outside air was also implemented in all case buildings. Heat pumps and district heating were in every case building, and district cooling connection was in four case buildings. The basic principle of each system was to use the heat pump to produce as much basic heating energy as possible and the remaining top-up heating with district heating.

The benefits of the commissioning process starting from the project predesign phase should be made better known to the professionals of the HVAC and building industry. International commissioning guidelines compiled by ASHRAE and REHVA are very comprehensive, but many people working in the field of HVAC technology have probably never heard of these [1,2,5]. For better publicity of the commissioning process in Finland, the commonly used RT instructions [3-4] should be updated with new commissioning process instructions, which are based on international guidelines [1,2,5]. Involving the commissioning provider from the beginning of the project and predesign phase inspections should be added to the Finnish instructions first.

The building owner/investor should also be made to understand that it is worth investing in the hybrid heating system commissioning process. The implementation of the hybrid heating system project is largely in the hands of the end user. The customer must understand the importance of the commissioning process for the hybrid heating system life cycle. Hybrid heating systems are life-cycle investments and thus the correct operation of the system must be guaranteed throughout its life cycle for the savings to be realized. It is senseless to invest in expensive hybrid heating system equipment if all of its possible benefits are not reached. If the hybrid heating system runs only on a backup heat source such as district heating or electricity boilers, the energy costs increase many times over the set targets. Thus, if a hybrid heating system investment is made, its correct operation during the life cycle must be guaranteed, because the payback period of the system is largely based on the energy consumption of the building.

Commissioning process costs are small compared to the savings produced during the life cycle of a large hybrid heating system. Ongoing commissioning and comprehensive monitoring of the hybrid heating systems are very important to verify that energy is produced and used in an optimal way. Ensuring the hybrid heating system operation also supports the maximizing of environmental benefits, when all the environmental and energy-saving potential can be achieved. Therefore, desire and expertise are needed on the customer side right from the beginning of the energy-efficient heating project.

The responsible contractor of the hybrid heating system should be a professional contractor who is responsible for the implementation and operation of the entire hybrid heating system. The contractor should understand the equipment installation and system operation. Hybrid heating system contracts should not be divided into shared contracts. Hybrid heating system projects should be implemented as overall responsibility contracts. Using prefabricated systems has been found to reduce installation mistakes. The flow of information and cooperation between owner/investor, supervisors, equipment manufacturers, designers, and contractors are very important parts of high-performing hybrid heating systems.

The hybrid heating systems can be made to work when the overall responsibilities and the responsibilities of the parties involved in to project are precisely defined. Here are a few ways as an example:

· The project should have a competent commissioning provider who should guide the entire project from predesign to ongoing commissioning.

· One proficient contractor should be responsible for the entire hybrid heating system installation.

· The whole system could be based on a life-cycle responsibility model, in which the property owner buys ‘heat as a service’ from the hybrid heating system owner/implementer.

Finding a qualified and professional commissioning provider is also a challenge for better commissioning process execution in hybrid heating systems. Currently, there is a lot of demand for experts related to HVAC and building energy efficiency. The commissioning provider should be an experienced specialist in HVAC and automation systems and understand the complete operation of the hybrid heating system equipment. A classification should be developed for evaluating the competence of the commissioning provider. For example, to analyze the commissioning provider’s references and experience in similar projects, a competence assessment and testing similar to the ASHRAE training agenda and training evaluation could be done [1-2].

The lack of education and unawareness of the hybrid heating systems are also a big challenge. There is no direct education for HPs and hybrid heating systems at any level. Hence, there are a lot of self-taught people working in the field and the instructions are partly incomplete. It has also been noticed that not all HVAC designers have the required skills to design hybrid heating systems. Education related to hybrid heating systems should be improved and courses about the cooperation of the different heat pumps, additional heat sources, energy recycling, and automation should be organized.

This study is funded by TALOTEKNIIKKA 2030 programme.

[1] ASHRAE. (2018). CommissioningProcessforBuildingsandSystems, ANSI/ASHRAE/IES Standard 202.

[2] ASHRAE. (2019). The Commissioning Process, ASHRAE Guideline 0.

[3] Finnish Building Information Foundation RTS. (2018). RT 10-11301, Talotekniikanlaadunvarmistus-ja vastaanottomenettely.

[4] Finnish Building Information Foundation RTS. (2018). RT 10-11302, Talotekniikanlaadunvarmistus-ja vastaanottomenettely, tehtävät ja dokumentointi.

[5] REHVA. (2019). REHVA Guidebook No. 27 - HVAC Commissioning Process.

Follow us on social media accounts to stay up to date with REHVA actualities

0