Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

|

|

|

KEVIN WINIARCZYK | OLAF OOSTING | TILLMANN KLEIN ⴕ | ATZE BOERSTRA |

Msc. TU DelftValstar Simonisk.winiarczyk@valstar-simonis.nl | Managing directorValstar Simonis | Professor BuildingProduct InnovationTU Delft | Professor Building Services Innovation TU Delft & managing director bba binnenmileu |

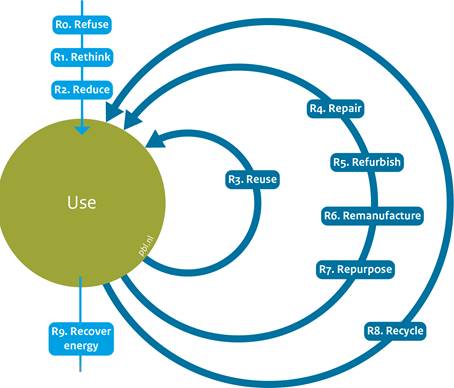

Over the past years, different circular economy principles have been introduced to promote the shift towards a more sustainable environment by minimising waste and circulating products at their highest value by optimal use and reuse of materials [1]. Therefore, a circularity ladder is developed (R-ladder) that includes various R-strategies to reduce raw material usage as illustrated in Figure 1. For circular strategies (R0-R2) high on the ladder fewer materials are needed and are more often made from (secondary) recycled materials [2]. Leading to an environmental impact reduction due to the avoidance of raw material extraction.

Figure 1. R-ladder circularity strategies [2].

The transition to a circular economy in the HVAC industry is challenging and proceeds slowly, but yet is important to reach the goals of the Paris Climate Agreement. The Dutch government set the goal for new buildings and their components to be fully circular by 2050 and aims for a 50% reduction in building-related raw material usage in 2030 [3].

Air duct components for ventilation in utility buildings, including schools, offices and hospitals are often made out of (corrugated) sheet metal as a non-renewable material. The use of high-density metals in HVAC systems, including air ducts, results in relatively high environmental impacts and adds substantially to the overall carbon footprint of buildings [4].

Moreover, a building consists of different layers each with their specific lifespan as presented in Figure 2. Where HVAC systems (including air ducts) are usually designed for just 15 years, other building components like floors and interior walls are often designed for 50 years or more [5]. Consequently, leading to more replacements and increased use of non-renewable raw materials over time.

Figure 2. Concept of shearling layers [5].

Achieving the Dutch government's goals requires an urgent change in how HVAC system components and specifically air ducts are designed. Alternatives possibly can be found in renewable bio-based materials to prevent the usage of high-energy raw materials and the depletion of resources [6].

This research aimed to explore the potential and limitations of bio-based materials to replace sheet metal by maintaining the same quality.

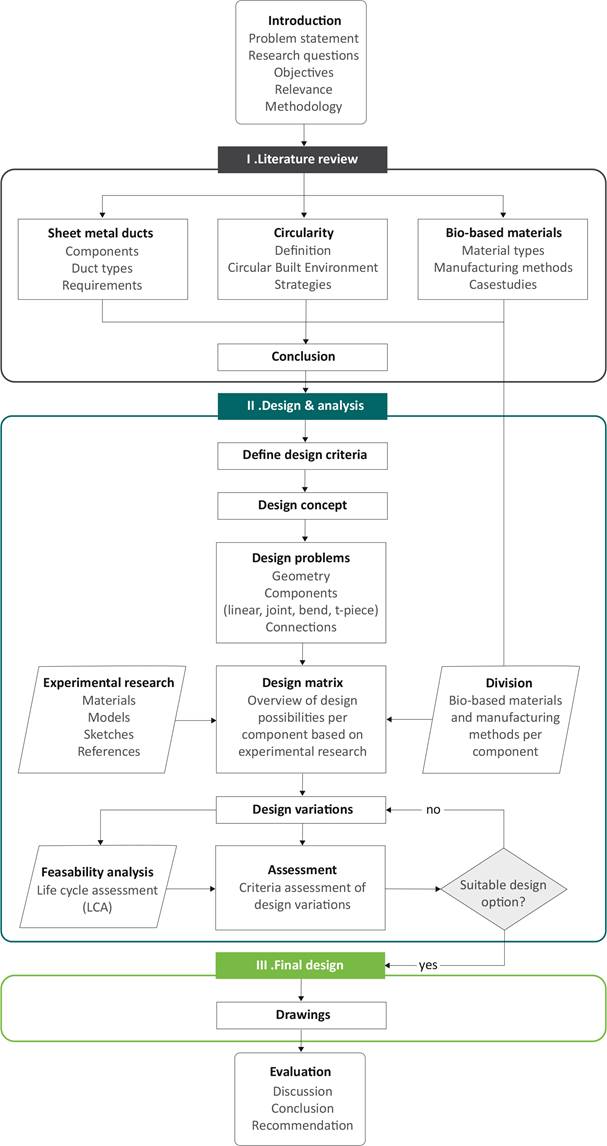

The research project was divided into three main parts: literature review, design and analysis and final design as visualised in Figure 3.

Figure 3. Visualisation of research steps and overall methodology.

First, the general literature was explored to identify how standard sheet metal air ducts and their components are constructed and produced, regarding shape, components, production methods and important design criteria.

In terms of circularity, the definition and relevant strategies were studied to gain insights into how the value of products can be extended. Mainly by delving into the theory of the R-ladder, consisting of strategies such as reuse, recycling and remanufacturing.

Additionally, bio-based materials and related manufacturing methods were explored, including case studies of bio-based products to understand the material workability. Accordingly, a methodology was developed that classifies the bio-based materials and manufacturing methods based on their production efficiency per type of component.

Next design criteria were formulated for the concept development of bio-based air duct components. Therefore, the following design aspects were defined:

· geometry, base assumption: round duct

· type of components: including linear duct, joint, bend and t-piece

· connections: aim for adaptable and airtight connections between components

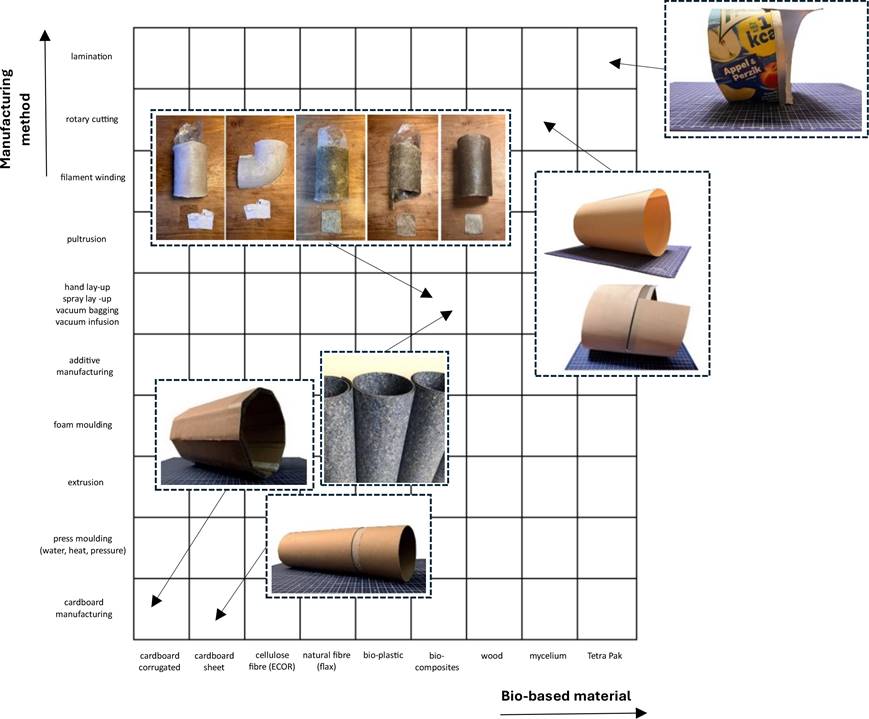

After this several bio-based ventilation duct design options were formulated. The functionality of these different options was compared with each other. A design matrix was created with bio-based materials on one axis and related manufacturing methods on the other axis. The functionality of the options was assessed by doing experimental research, and through modelling with bio-based materials, as well as by analysis of references. Leading to a selection of promising options, at this stage recycled plastic was added as a possible alternative. These options were evaluated according to the most critical requirements to analyse if the quality of sheet metal ducts could be achieved. This included a LCA analysis, to evaluate the carbon footprint of the distinct solutions, in which a comparison was made with sheet metal as a benchmark.

During the final design phase, the design option with the best performance was further developed into a detailed design.

Based on the literature a long list of requirements was formulated, divided into five categories related to functionality, circularity, manufacturing, installation and use. From these categories the most important criteria were selected for the evaluation of the selected design options in a later stage:

· Moisture resistance: the resistance against moisture due to condensation or a humid environment.

· Chemical emission: concentration of volatile organic compounds (VOCs) or formaldehyde in the material, respectively for (bio) plastics, bio-resins and (wood) veneer.

· Carbon footprint: the environmental impact of the product (assessed roughly by comparing embodied energy).

· Renewability: the potential of circular strategies related to the R-ladder, reuse and recycling.

· Material workability: the ease of installation which relates to the weight and robustness of the material.

· Mass-production: the ease of scalability in quantity and sizes.

The criteria mentioned above were mandatory for the selected bio-based materials to meet the quality of sheet metal duct components. Fire safety was not included in this list. Since there are no specific requirements for installed ducts as long as they are inside one fire compartment. Nevertheless, certain bio-based materials are more flammable (indicated with fire classes) for indication) than others and therefore a higher risk.

Preliminary to the experimental research the selected bio-based materials derived from the literature review were divided based on their manufacturing efficiency per type of component. Leading to a division between linear and complex components, including joint, bend and t-piece. See Table 1 for the outcomes of this first material option analysis.

Table 1. Division manufacturing methods per type of component and bio-based material.

Linear components Linear duct | |

Bio-based material | Manufacturing method |

Cardboard | Spiral winding |

Cardboard | Lamination |

Veneer | Rotary cutting |

Bio-plastics | Etrusion |

Bio-plastics | Foam moulding |

Bio-composite fibres | Pultrusion |

Bio-composite fibres | Filament winding |

Natural fibres | Weaving |

Cellulose fibres | Water, heat & pressure moulding |

Bio-composite non-woven fabric | Compression moulding |

Tetra Pak | Lamination |

Complex components Joint, bend, t-piece | |

Bio-based material | Manufacturing method |

Cardboard | Lamination & cutting |

Bio-composite woven-fabric | Hand lay-up |

Bio-composite woven-fabric | Spray lay-up |

Bio-composite woven-fabric | Vacuum bagging |

Bio-composite woven-fabric | Vacuum infusion |

Bio-composite non-woven fabric | Compression moulding |

Bio-plastics | Additive manufacturing |

Bio-plastics | Injection moulding |

Mycelium | Moulding |

Tetra Pak | Lamination |

During the experimental research, the criteria were considered for the development of design options and placed in the design matrix as presented in Figure 4. Therefore, a selection of materials was explored each with a specific manufacturing method, including corrugated cardboard, cardboard tubes, bio-plastics, two variants of bio-composites, (wood) veneer and Tetra Pak.

A lot of material testing was conducted to figure out which solutions were more promising than others. The first design options were created with cardboard.

Corrugated cardboard sheets were explored, which seem beneficial for efficient transport and are easy to assemble. However, only a polygonal shape can be made which makes connections between components more challenging.

Alternatively, round cardboard tubes are robust, easy to manufacture into a circular shape and scalable. However, cardboard is barely moisture-resistant which could lead to damage over time.

We also produced several test pieces that use (wood) veneer. Veneer looks aesthetically pleasing but has its downsides. The material is expensive, very fragile and sensitive to temperature and humidity changes. Therefore, fulfilling the functional requirements and maintaining a round geometry is hard.

Figure 4. Design matrix bio-based materials and manufacturing methods [7].

Next bio-composites were explored. These consists of at least two materials with different properties, in this research respectively:

· a reinforcement material; e.g. woven and non-woven flax fibres as well clothing waste (t-shirts and jeans)

· and a binder; e.g. based on epoxy bio-resin and epoxy hardener.

By combining both materials the mechanical properties can be improved, resulting in a robust design option. However, the production of large components made in this way is time-consuming and expensive.

Lastly, we looked at the option ‘Tetra Pak’. This refers to layered material developed for the food industry (well-known from e.g. juice packaging) and is a suitable material in terms of hygiene and cleanability, is lightweight and reasonably strong. In our opinion a suitable basic material for making linear duct components. Even though the material does not seem bio-based, a 95% bio-based content is achieved nowadays: this includes mainly paperboard as well as inner and outer layers of bio-plastic. The last part contains an inner layer of aluminium. The material layers are laminated together, making it a successful moisture-resistant (packaging) material that e.g. is very smooth and easy cleanable.

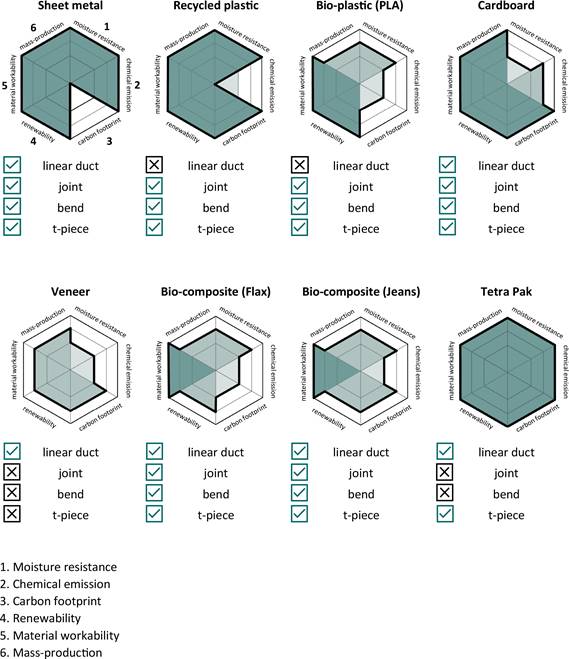

The different duct design options were assessed according to the most important criteria. A score was assigned between 0 as the most negative and 3 as the most positive as illustrated in Figure 5.

The quality of sheet metal ducts is hard to match for most materials, many bio-based options scored poorly on the aspects of chemical emissions and moisture resistance.

Chemical emission is challenging for linear (bio)- plastic and bio-composite components due to the possible high concentration and emissions of volatile organic compounds (VOCs). Which could lead to potential health problems, e.g. irritation of mucous membranes of building occupants. This also applies to formaldehyde in veneer solutions.

Moisture resistance also often is a problem due to the characteristics of bio-based materials, which increases the risk of moisture absorption.

Figure 5. Material and component evaluation based on key criteria.

Only Tetra Pak scores well on all aspects including moisture resistance, making it suitable for linear and (some parts of) t-components.

Well recycled plastic as an alternative for bio-based materials scored well too, besides for chemical emissions. In comparison to bio-based plastic, recycled plastic significantly scores better on the carbon footprint due to the recycled content. Furthermore bio-plastics, in this research PLA was assumed, are often biodegradable and thus pose more risk for moisture issues.

Conclusion: recycled plastic should be the most suitable material for smaller complex components and this could be combined with Tetra Pak material for the linear components (the ducts themselves).

Different design components ask for specific efficient manufacturing methods. Meaning that not all components can be produced from the same (bio-based) material and that we need to accept that linear components could be made of other materials than the complex parts.

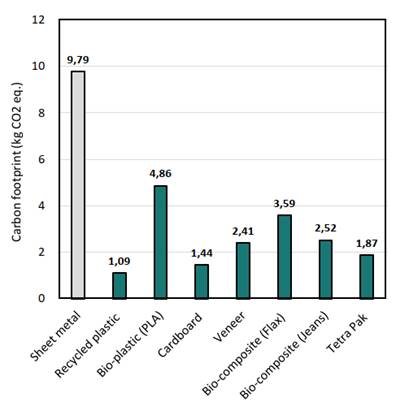

Apart from the qualitative comparison presented above we also executed LCA calculations to compare the carbon footprints of the different design solutions.

Uniclima [8] conducted a LCA analysis for a round sheet metal duct (65% raw material usage, 35% recycled material), with a diameter of 160 mm, a thickness of 1 mm and a length of 1000 mm, which was taken as a reference for equal comparison with the selected materials. The thickness for the (bio-based) materials was based on the findings of the experimental research. Which vary between 2 mm for recycled plastic, bio-plastic, bio-composites and Tetra Pak, and 3 mm for cardboard and veneer. In practice the thickness may differ for the solutions, therefore the LCA calculations should be corrected for practical cases. Data for the LCA calculations was derived from the database of Idemat [9] and assumptions were made for unknown data. Additionally, an assumption was made that no energy is used during the installation (A5) and use phase (B1-B7). A comparison of the LCA outcomes for the different materials is presented in Figure 6 and Table 2.

Sheet metal shows the highest environmental impact, at least twice as high as the selected materials. Recycled plastic has a significantly lower impact than bio-plastic, which makes it more likely to apply recycled plastics instead. Veneer, Tetra Pak and cardboard turn out to be the most advantageous, with respectively a factor of 4 to 7 lower compared to sheet metal.

Table 2. Carbon footprint per material based on a linear duct with a diameter of 160 mm and a length of 1000 mm, the thickness varies per material [8-9].

Material | Unit (per meter) | Total | A1-A3 Manufacturing | A4 Distribution | A5 Installation | B1-B7 Use | C1-C4 End of life |

Sheet metal | kg CO₂ eq. | 9,79E+00 | 8,39E+00 | 1,14E+00 | 0,00E+00 | 0,00E+00 | 2,69E-01 |

Recycled plastic | kg CO₂ eq. | 1,09E+00 | 1,06E+00 | 1,50E-02 | 0,00E+00 | 0,00E+00 | 1,50E-02 |

Bio-plastic (PLA) | kg CO₂ eq. | 4,86E+00 | 4,84E+00 | 1,00E-02 | 0,00E+00 | 0,00E+00 | 1,30E-02 |

Cardboard | kg CO₂ eq. | 1,44E+00 | 1,13E+00 | 1,00E-02 | 0,00E+00 | 0,00E+00 | 3,00E-01 |

Veneer | kg CO₂ eq. | 2,41E+00 | 1,84E+00 | 1,00E-02 | 0,00E+00 | 0,00E+00 | 5,60E-01 |

Bio-composite (Flax) | kg CO₂ eq. | 3,59E+00 | 3,50E+00 | 1,50E-02 | 0,00E+00 | 0,00E+00 | 8,25E-02 |

Bio-composite (Jeans) | kg CO₂ eq. | 2,52E+00 | 2,45E+00 | 1,20E-02 | 0,00E+00 | 0,00E+00 | 6,38E-02 |

Tetra Pak | kg CO₂ eq. | 1,87E+00 | 1,67E+00 | 1,00E-02 | 0,00E+00 | 0,00E+00 | 1,89E-01 |

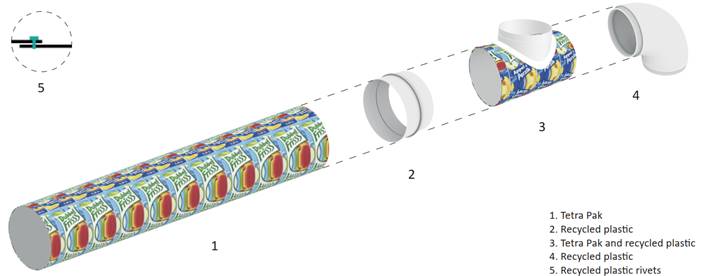

According to the assessment, Tetra Pak turns out to be the most suitable solution for linear duct components. The overall score, see combined outcomes presented in Figure 5 and Table 2, for this material was best. Lamination as a production method (already developed for the food industry) makes it possible to produce large sheets consisting of different material layers, which can be separated and recycled at the end-of-life phase. Moreover, Tetra Pak has been developed in a way that it consists of the majority of bio-based content.

As far as the more complex duct parts are concerned: the analysis showed that for joints and bends recycled plastic is the best option, by using injection moulding as a production method.

Figure 6. LCA comparison based on comparison of embodied energy for selected (bio-based) materials and sheet metal.

The t-piece should be constructed from a combination of both materials, bonded together with a strip of heated thin film bio-plastic since the overall geometry is too complicated to produce only from Tetra Pak as visualized in Figure 7.

For the connections, plastic rivets (made from recycled plastic) turn out to be most beneficial compared to adhesives, tape (single or double-sided), bolts and click connections. However, this requires more development since applying rivets or any other type of connection penetrating through the material will lead to damage and increase the risk of moulding. Therefore, connections should be designed more carefully, as well concerning airtightness and adaptability.

Figure 7. Final design Tetra Pak solution with complex components made out of recycled plastic (note: in real life projects of course one can print whatever one likes on the outer side of the duct material)

This research project explored whether it was possible to produce air duct components from bio-based materials with comparable functionality to sheet metal. In terms of the environmental impact derived from the LCA calculations, materials including Tetra Pak and cardboard, show significantly lower results than standard sheet metal solutions. If the mentioned thicknesses can be achieved in practice. Also, the qualitative analysis (see Figure 5) showed that Tetra Pak is the best option for the linear components and that recycled plastic is the best option for the complex components, including joints, bend and t-piece.

The results show that due to the difference in geometry, a division in linear and complex duct components is needed for the efficient production of bio-based air duct components. Leading to a combination of suitable materials. Nevertheless, achieving the quality of sheet metal ducts turned out to be challenging for most bio-based materials, including cardboard, veneer, bio-plastic and bio-composite due to the weak moisture resistance and chemical emission of the material.

Overall, further research is needed to find out what the lifespan of the suggested solution is, e.g. by setting up pilot projects which can give insights into how bio-based air duct components react in practice when exposed several months or years to temperature and humidity changes.

Another question is if there are also more circular alternatives possible for other type of building installation components. It would be good for example to conduct further research into whether you can make air handling units or heat pumps (partly) from bio-based materials.

[1] Ellen MacArthur Foundation. (2023). What is circular economy? Retrieved from https://ellenmacarthurfoundation.org/topics/circular-economy-introduction/overview

[2] PBL. (2018). Circular Economy: What we want to know and can measure. Retrieved from http://pbl.nl/

[3] Rijksoverheid. (2016). Nederland circulair in 2050. Retrieved from http://www.rijksoverheid.nl/onderwerpen/circulaire-economie/nederland-circulair-in-2050

[4] Copper8. (2023). Utiliteitsbouw binnen planetaire grenzen. Materiaalvraag, CO2-uitstoot & milieu-impact van de nederlandse utiliteitsbouw. Retrieved from http://www.copper8.com/

[5] Brand, S. (1994). How Buildings Learn: What Happens After They’re Built. London, UK: VikingPress.

[6] TU Delft. (2020). 2.1.4 Bio-based Products in the Built Environment. Retrieved from http://www.ocw.tudelft.nl/course-readings/2-1-4-bio-based-products-in-the-built-environment/

[7] PlanQ. (2022). Rezign Veneer. Retrieved from http://www.planqproducts.com/

[8] Uniclima. (2023). Joint Production Environmental Profile. Metal circular air duct. Retrieved from https://www.register.pep-ecopassport.org/

[9] Idemat. (2022). Idemat and Ecoinvent and ecocosts midpoint tables. Retrieved from https://www.ecocostsvalue.com/data/

Follow us on social media accounts to stay up to date with REHVA actualities

0