Stay Informed

Follow us on social media accounts to stay up to date with REHVA actualities

|

Jan Hensen |

Em.prof.dr.ir. |

When I was a teenager, the Netherlands made a significant change in its energy source, switching from coal and city gas to natural gas. This switch led to an improvement of thermal comfort in homes, but it also resulted in higher fossil fuel consumption. However, concerns about the environment and need for energy savings soon arose, prompted by events like the 1973 energy crisis and the need to address climate change. These factors have motivated researchers and experts to focus on improving building performance and transitioning to renewable energy sources.

However, it's important to remember that energy use is just a means to achieve the real purpose of a building: to protect against external influences and provide a comfortable and healthy indoor environment. As awareness of health and well-being increases, there is a growing shift towards prioritizing indoor environmental quality rather than just energy-related performance.

The building sector faces various other challenges, such as involving multiple stakeholders, ensuring long-lasting and adaptable structures, and dealing with unique designs and construction processes. To overcome these challenges, innovative building solutions are required. These solutions need to be thoroughly analysed to understand how they can be optimized and integrated into existing or new buildings for long-term effectiveness.

The ultimate goal is to create sustainable built environments with zero-carbon emissions, where indoor environments are optimized for health, comfort, and productivity. Achieving this requires collaboration between different technical and non-technical disciplines.

From my perspective, building performance modelling and simulation can play a very efficient and effective role in this context [Hensen and Lamberts 2019].

Modelling involves creating simplified computer-based representations of real systems to focus on essential aspects of complex problems while excluding irrelevant details. Simulation, on the other hand, uses models to predict the behaviour of real systems in the future. Simulation is a powerful tool for analysis and understanding, although it does not directly generate solutions or answers.

Research and development of building performance simulation began in the 1960s, initially focusing on modelling and software features. However, attention has shifted towards improving the effectiveness of building performance simulation throughout the various stages of a building's life cycle. Let’s introduce some applications we have been working on.

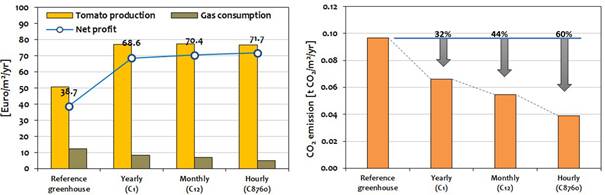

Building simulation allows to explore “wild” ideas such as dynamically adapting the thermal and optical properties of greenhouse covers based on weather and crop requirements. While it is not yet possible in the real world, simulations allow us to change these properties and evaluate their potential impact energy savings and increased crop growth.

Figure 1. Predicted crop production, gas consumption and CO₂ emission for a generic reference greenhouse; one in which the optical and thermal properties are constant and optimized over the year for tomato production (C1) or where optical and thermal properties can change and are optimized per month (C12) or per hour (C8760). Costs and profit are based on 2015 prices. [Adapted from Lee et al. 2019]

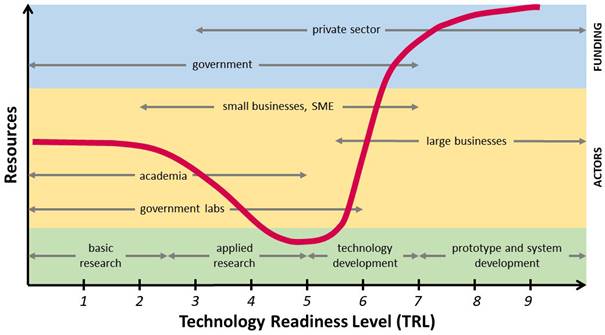

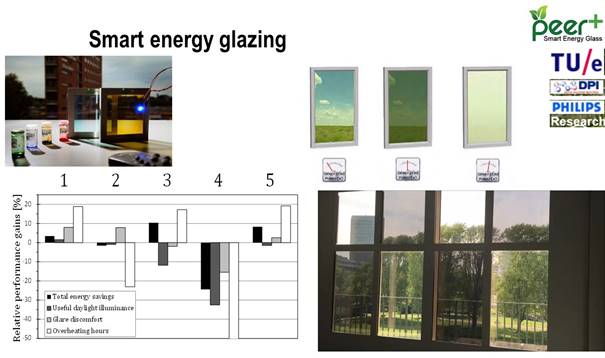

Advances in material sciences offer opportunities for new building envelope technologies, such as vacuum insulation and phase change materials. Building performance simulation can help overcome challenges in the intermediate stages of research and development by providing insights into building integration issues and evaluating the performance of new materials. For example, smart energy glass is a technology that combines liquid crystalline materials with window integrated PV cells to create fast-switching, self-sufficient switchable glass. By regulating the amount of daylight and solar gains they transmit, absorb and reflect, these windows offer options for improving energy performance and comfort conditions.

Figure 2. Availability of resources for new product development at various TRLs. Building simulation can help overcome the gap in the middle which is sometimes referred to as “The Valley of Death”. [Loonen 2018]

In this case the use of simulations started during a very early R&D phase (TRL 2-3) when the technology was only available in the form of small-scale samples. We predicted whole-building performance in terms of comfort and energy saving potential under a range of operating conditions and building use scenarios. Based on this information, benchmarks were set and specific material-level development targets were outlined.

Figure 3. Smart energy glazing performance. Options 1-5 represent different control strategies. [Adapted from Loonen et al. 2014]

Building performance simulation is valuable when designers and engineers have doubts about certain (innovative) building design features. It can be used for risk analysis and optimization of mitigation measures. In that sense we have been involved in, for example, assessing the performance of double-skin facades, sizing appropriate air-conditioning systems for historical buildings, evaluating draft levels in underground train stations, and analysing indoor environments and condensation risks in unique structures like tropical zoo pavilions. Apart from risk analysis, the most common use in everyday practice is for checking compliance with building regulations.

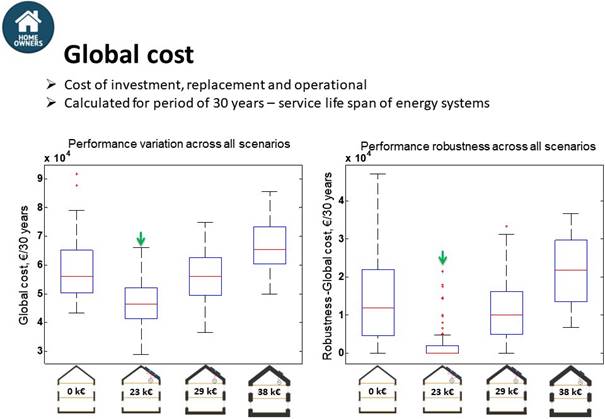

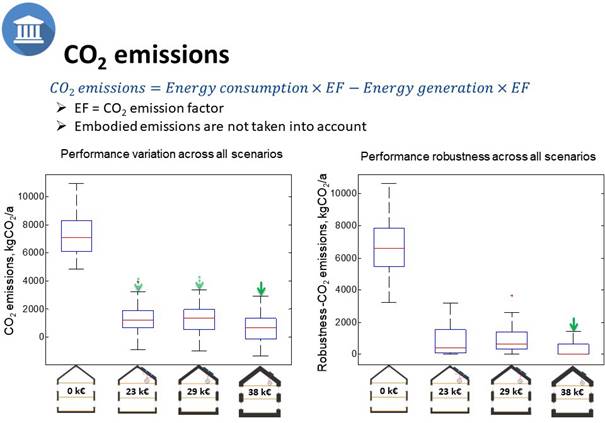

A very interesting application is optimization under uncertainty, which is relevant in e.g. robust energy-efficient retrofitting of houses. Uncertainties in building operation and external factors such as occupant behaviour, climate change, energy prices, policy changes etc. impact future building performance, resulting in possible performance deviation during operation compared to the performance predicted in the design phase. The probability of occurrences of these uncertainties are usually unknown and, hence, scenarios are essential to assess the performance robustness of buildings. Therefore, a non-probabilistic scenario analysis, has been developed to identify robust designs. Maximum performance regret calculated using the minimax regret method is used as the measure of performance robustness. In this approach, the preferred robust design is based on optimal performance and performance robustness.

Figure 4. Predicted global cost for different renovation packages aiming at annual net zero-energy for a 1992 house assuming a wide range of occupant behaviour and climate change scenarios. The right-hand graph shows robustness in terms of regret (= performance difference between the solution considered and the best performing solution for a particular scenario). [Adapted from Kotireddy et al. 2018]

Consider the case of a 1992 single-family home that has to be converted to net zero-energy by adding extra insulation for demand reduction and PV panels for energy generation. The investment cost will depend on the insulation level and the number of PV panels.

The preferred solution depends on the viewpoint of the stakeholders. Assuming that home owners are very likely most interested in investment and operation costs, they would probably prefer the solution with not so much extra insulation but with a rather large number of PV panels. The government, however, is committed to putting CO₂ emission reduction policies in place. From the results it is clear that the solution with more insulation would be more effective in that context.

Figure 5. Predicted CO₂ emission for different renovation packages aiming at annual net zero-energy for a 1992 house assuming a wide range of occupant behaviour and climate change scenarios. The right-hand graph shows robustness in terms of regret (= performance difference between the solution considered and the best performing solution for a particular scenario). [Adapted from Kotireddy et al. 2018]

Building simulation is also very useful for supporting post-construction activities. By integrating computational and physical processes, cyber-physical systems enable testing and optimization of control strategies without disrupting real-world operations. Further development of this approach could lead to the creation of digital twins, which combine physical systems with digital copies to forecast the behaviour of real products in real time.

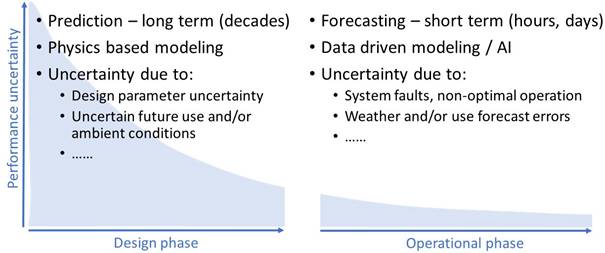

When it comes to optimizing building energy, there are significant differences between the design phase and the operational phase. Design choices can greatly impact predicted energy use, with a wide range of potential outcomes. Modifying a building after completion is challenging, whereas updating building energy management software is relatively easier.

During the design phase, we have to consider a vast range of design options, uncertain future conditions, and long-time horizons. Since new innovative solutions lack performance data, we rely on deterministic modelling approaches based on physics rather than data-driven methods.

Figure 6. Main differences in performance uncertainty emanating from simulations in the design or operational phase of a building.

Once a building is constructed and operational, real performance data becomes available. This data can be used for data-driven modelling and other artificial intelligence-based modelling and simulation approaches. The time horizon of interest is much shorter than during design (think of hours and days rather than decades). Use and boundary conditions are “known”. Therefore, deviations between forecasted and real energy use are likely to be attributable to system faults or non-optimal operation. Hence, typical applications are fault detection and diagnostics, smart maintenance and control optimization.

Quality assurance is crucial for simulation-based decisions. The quality of simulation results depends in the first place on the correctness of the model and the input parameters; in other words, are the predicted numbers correct? Most of the time they are not, which results in the so-called performance gap. This difference between predicted and real measured energy performance is caused by issues during the design phase (e.g. model limitations, input parameter assumptions); the construction and commissioning phase (e.g. construction flaws, differences between assumed and actual materials, components and systems); and the operation phase (e.g. systems not working properly and/or differences between assumed and actual building usage).

Energy label calculations mostly ignore these uncertainties. Labels are not meant to indicate future energy use and, therefore, should not be interpreted as such.

Since building energy simulation is now at the level where incorporation of uncertainty and sensitivity analysis is feasible, the results should always be presented with uncertainty ranges and preferably with sensitivity analysis outcomes as well.

The quality assurance of results for simulation-based decisions depends on much more than only the physical correctness of the model. The quality of the end result (i.e. the results to be communicated to decision makers) can only be “assured” when it is based on quality assurance during every step of a simulation study. This begins with the relevance and accuracy of the problem formulation.

The examples illustrated above are really based on different problems communicated by different stakeholders. Therefore, they need to be approached differently. It is not even always the best approach to use modelling and simulation – sometimes the problem can be solved by common sense or it would be better to use physical experiments.

It is crucial to start with validation, verification and testing in this initial phase and continue with it throughout the full life cycle of a simulation study. The procedures for doing this are known from other research fields (e.g. operations research) but they are not often used in our field. Since we have been teaching this to our students for many years now, it is hopefully only a matter of time before they become common practice.

Thorough domain knowledge is paramount for assuring the quality of simulation results and conclusions. Nowadays, modelling and simulation are taught from the early education stages onwards. Therefore, our simulation courses and student projects can focus on specific building performance modelling and simulation skills along with knowledge about principles, assumptions, limitations, when to use and when not.

The ability to identify valid information from incorrect information is a very important skill to have. Credibility as a professional, hinges on the accuracy of the information they will use. Thus, learning how to assure the quality of simulation results is an overarching goal and very important, because poor quality or wrong information may have severe consequences for the built environment and human well-being.

The challenges faced by the built environment require intelligent individuals armed with appropriate knowledge and smart approaches. Building performance simulation is a vital tool in our pursuit of better buildings. I hope to have conveyed the significance of this field and the potential it holds for creating sustainable and efficient structures.

Hensen, J.L.M. and Lamberts, R., ed., 2019. “Building Performance Simulation for Design and Operation; Expanded second edition”, Routledge. https://doi.org/10.1201/9780429402296.

Kotireddy, R.R., Hoes, P. & Hensen, J.L.M., 2018. A methodology for performance robustness assessment of low-energy buildings using scenario analysis. Applied Energy, 212: 428-442. https://doi.org/10.1016/j.apenergy.2017.12.066.

Lee, C., Hoes, P-J., Costola, D. & Hensen, J.L.M., 2019. Assessing the performance potential of climate adaptive greenhouse shells, Energy, 175: 534-545. http://dx.doi.org/10.1016/j.energy.2019.03.074.

Loonen, R.C.G.M., Singaravel, S., Trcka, M., Cóstola, D. & Hensen, J.L.M. 2014. Simulation-based support for product development of innovative building envelope components, Automation in Construction, 45, 86-95. http://dx.doi.org/10.1016/j.autcon.2014.05.008.

Loonen, R. C. G. M., 2018. Approaches for computational performance optimization of innovative adaptive façade concepts, doctoral dissertation, Built Environment. Technische Universiteit Eindhoven. https://research.tue.nl/files/102239772/20180906_Loonen.pdf.

Follow us on social media accounts to stay up to date with REHVA actualities

0